Special products require special storage conditions. As you might already know, most pharmaceutical products are very temperature-sensitive and have to be stored in a specific temperature zone. Doesn’t matter if it’s dry ice with -78° or moderate cold storage conditions from 15-25° Celsius, even small fluctuations in temperature can lead to the full unusability of the product. To avoid this kind of financial and environmental disaster but also to follow the Good-Distribution-Practice (GDP) temperature maps of your warehouse can be extremely helpful. Therefore, we created a list of 5 vital steps for warehouse mapping that help you to get to know your warehouse like your living room.

1. Map the whole warehouse

Just because two or three measurement points are inside the desired temperature range, it doesn’t mean that your whole warehouse has the perfect temperature. Even the most state-of-the-art air conditioning can’t guarantee the same temperature in the whole building. Spots closer to the fan or air conditioner are colder than the ones further away. Places behind corners have worse air circulation compared to ones in a straight airflow from the cooling system.

Therefore, it is important to have enough measuring points. To save time and get accurate measuring results we highly recommend using data logging temperature sensors.

2. Identify and cover the trouble-making spots

As already mentioned above, some spots require special treatment. Not only different heights but especially external factors can influence the temperature of your warehouse. For example, doors with a lot of traffic or windows and hatches absorbing outside heat are such trouble areas. Additionally, the south-facing side of your building is most likely to have a higher temperature than the northern side. Because every warehouse is built and used differently, you must keep your eyes open, check potential troublemakers and make sure these spots are covered by temperature sensors. Once such a spot is discovered, there is the possibility to react to it. How quickly you recognize temperature fluctuations also depends on the equipment you are using. While USB loggers need to be collected, put into computers and read out by an employee manually, there more advanced solutions reading out the collected data automatically. Read on to gather more information about Smart Data loggers.

3. Take your time to create the temperature mapping

During the entire day, the temperature inside your warehouse will most likely vary by a few degrees. This has several reasons. Besides the fact, that the outside temperature at night is of course lower than at midday, the temperature is affected by the number of employees working in the warehouse. Usually, this leads to higher temperatures during working hours, but also higher temperatures during the weekdays in comparison to the weekend. Additionally, the temperature of full warehouses can vary from empty ones due to different air circulation.

To master these challenges, it is recommended to map your warehouse not only for a few hours but several days in a row. This way you can avoid bad surprises in the long term.

4. Warehouse mapping requires updates

Unfortunately, just like a smartphone, your warehouses require temperature map updates from time to time. As already mentioned, warehouse temperatures depend on the used capacity. Therefore, you should map the temperatures at least once when your warehouse is completely empty, half-full, and also completely full. Furthermore, seasons have a big impact on cooling systems. To cover the peaks and lows of external temperatures it Is recommended to make at least two mappings each year – one in summer and one in winter. Last but not least, every time the design of a warehouse is changed, also the temperature zones inside it are affected. To cover these changes, you should carry out a new warehouse map.

5. Take advantage of innovative solution

Humans make errors. Starting from measuring inaccuracies, carelessness, or losing track of paperwork. Creating temperature profiles by hand or using old-fashioned methods will take you a lot of time and energy. In the worst case, it can lead to massive financial losses, if the stored goods are exposed to the wrong temperature for too long. Yet, it still doesn’t guarantee accurate and satisfying results. On the bright side, involving state-of-the-art smart equipment can save you a lot of trouble and headaches.

Tec4med’s smart solution for warehouse mapping

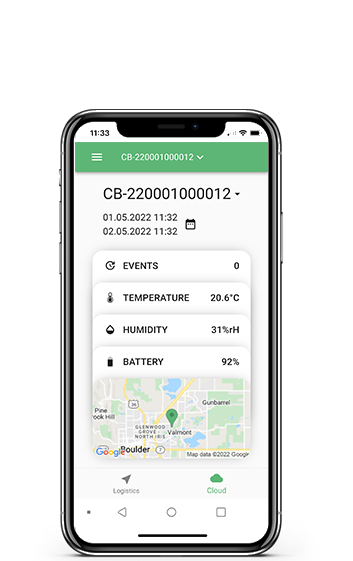

Proudly, we are presenting our innovative solution making warehouse mapping a lot easier. In customer-specific intervals, our SmartHub Gateways are reading out the data collected by intelligent Beacons in real-time. Not only temperature ranges from -200 up to +80 degrees, but also humidity, shock, and GPS are tracked by the system, and the data is sent to the Tec4Cloud. Via smartphone or browser, this data can be reviewed online at any time, which allows you to work 100% paperless.

Furthermore, the customer can choose to create alert settings. Whenever a certain temperature or humidity is reached, you receive a notification and react immediately.

Thanks to the popular “Plug & Play” principle the handling of the devices is very simple for every employee. After placing the Beacons at the desired measuring points inside your warehouse, you simply place the Gateways in strategic useful places to read out the data logging Beacons. A huge advantage is the flexibility of measuring points. Since no further installation is required, you can change the position of the Beacons. Besides, no cables at all are necessary, because the devices come with their power supply.

Conclusion: The right warehouse temperature is crucial

Knowing the temperature zones of your warehouse is one of the biggest steps for guaranteeing the best quality for your products. Without the security that every inch in your warehouse has the right temperature, there is always a risk of losing parts of your goods due to temperature fluctuations. Modern solutions help to avoid this kind of disaster by supporting you to create a temperature map of your warehouse and fix the problems mentioned above. All of this makes your job of keeping the highest quality for your customers a lot easier so that you can lean back in your living room without a bad feeling.

You can find our solutions in our webshop. In case you need help with your warehouse mapping or if you are interested in further application opportunities with our solutions you are more than welcome to contact our team: inquiry[at]tec4med.com