A life without e-commerce and online-shopping is hard to imagine. Since 2016 there are 3 billion deliveries a year in Germany alone. Inner cities are groaning with the number of delivery vehicles. Disposable packaging is a leading cause of rising environmental pollution. Solutions for the last mile, infamous within logisticians, are needed.

From the warehouse to the consumer, a package quickly travels a few hundred kilometers or more. The most significant difficulties are found in the last part of the journey, the delivery to the customer – so-called last mile. If something goes wrong here, the whole effort up to that point was for nothing.

Greatest challenges in the cities

This has become an issue, especially in urban areas. As a study from business advisory Price Waterhouse Cooper shows, between 20 and 30 percent of all city traffic is due to delivery vehicles. At the same time, they are accounted for up to 80 percent of all inner-city traffic jams.

One reason for this is the infrastructure of the cities. They were not ready for the enormous growth of delivery trucks. Cutouts in the streets are missing, most of the time the only solution for the delivery driver is to park in the second row.

Also, in many cases, the product can’t be delivered because no one is at home. In this case, the delivery is sent to a central pick-up station or a second delivery for the same order must be scheduled. So, the same order produces a second tour and adds up to the inner-city traffic and environmental pollution.

Science fiction becomes reality: drones and robots in action

Some solutions seem to be taken from the future, such as drones and robots. Anyhow, they’re already being used. A delivery via air directly to the front-door appears to be currently unrealistic. The risk of injury is still too high. Furthermore, it’s hard to get a flight allowance for urban areas. These allowances are necessary for drones, also.

German parcel service Hermes is testing its Starship robot in Hamburg since the beginning of 2017. The robot can carry packages up to a maximum weight of 15 kilograms. It moves at walking speed on the sidewalk, recognizing traffic lights and climbing small obstacles. This delivery version has its primary purpose in an urgent parcel, for example, medications.

Other countries are already a step ahead. The Chinese e-commerce company JD.com is using autonomously working robots in two rural areas of the country. One robot can carry up to 30 packages and deliver it within a radius of five kilometers. The person receiving the mail unlocks the home-delivery robot using face authentication. Up to 2000 deliveries, a day can be done like that.

Cooling while transportation

Especially in the last years, the options of e-commerce in the food sector have risen. Getting fresh products sent home and saving the way to the supermarket is the idea behind the concept. Ordering groceries online means some of the products are perishable. A lot of the deliveries need to be cooled to keep the food in good condition. There is one problem if no one is home to retain the distribution: the thermal cooling packs have a limited capacity, which makes a second delivery hard to take place. Besides, a significant amount of waste is produced by disposable cooling boxes.

Environmental pollution caused by passive cooling boxes

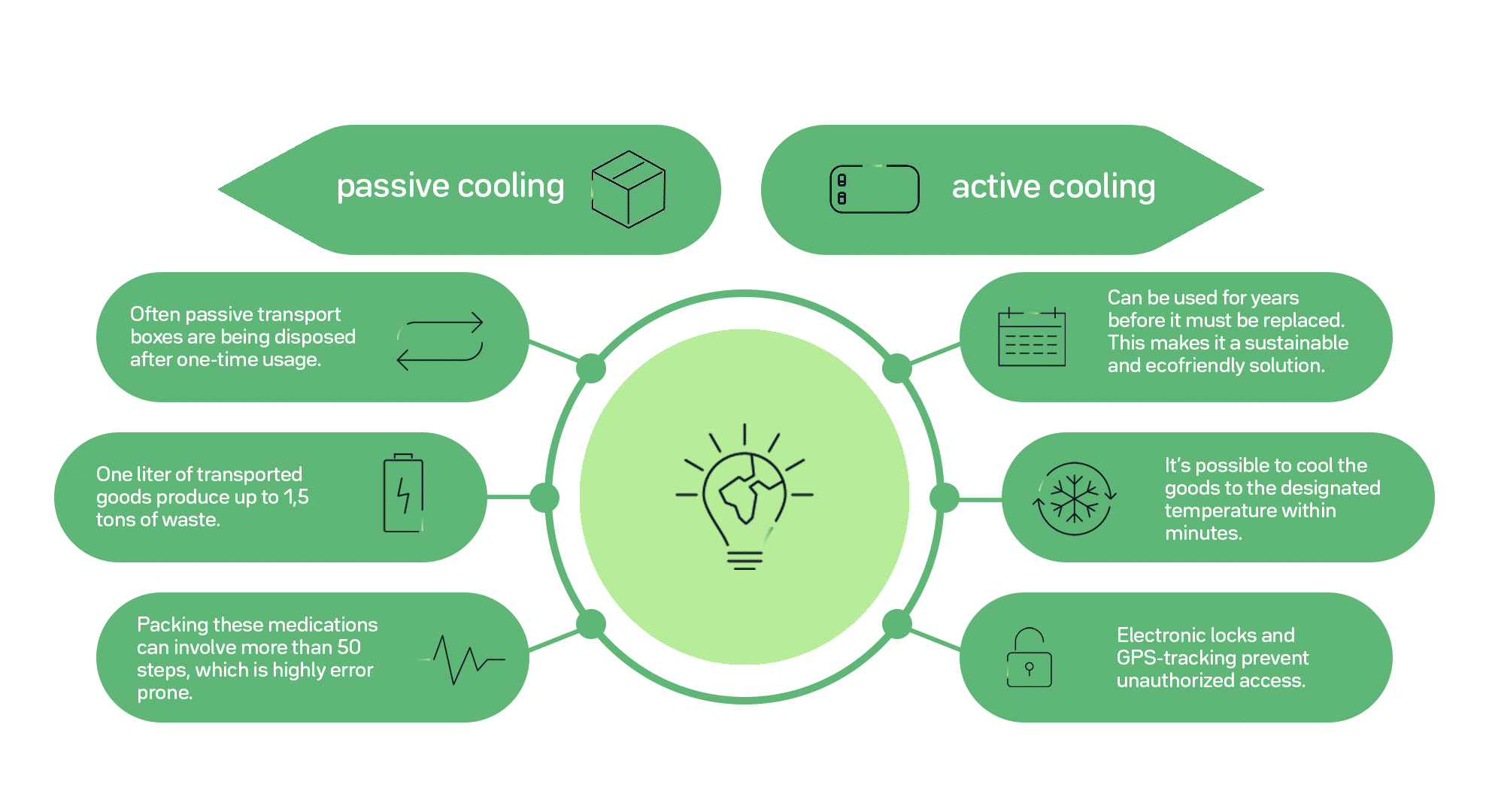

A lot of the passive transport boxes are disposed after one-time usage. Whether it was a disposable box or a reusable box is often ignored. Reusable box, in this case, means a maximum of five to seven transport cycles. After that, the boxes end up at the special waste because they got bashed up too much.

For single-use cooling boxes, one liter of transported goods produces up to 1,5 tons of waste. In the case of cartonnage, filled with thermal packs, the cardboard itself is easily disposable. The disposal of transport boxes which are made of polystyrene or similar materials is costlier. Polystyrene is made of petroleum with high use of energy. Frequent garbage dumps need high burning temperatures to get rid of the product. Also, concerning the environment, burning this material produces toxic gases that pollute the atmosphere.

Special focus: pharma and medications

Not only the delivery of passive cooling boxes is costly and harmful to the environment. Also, the steps before the delivery are a problem for years. Specially trained workers must pack several components into the passive boxes, which can only be done in designated cold storage houses. In the case of medication restricted to the cold chain, it must be packed in a way it won’t freeze during transportation. Packing these medications can involve more than 50 steps. This error-prone complexity leads to mistakes that can destroy the goods.

After packing the passive box, the process is not over yet. Proof of an unbroken cold chain is an obligation. Scandals about ruined meat being sold in German supermarkets happened not so long ago. The medication also gets corrupted if the needed temperature is crossed. The medicine may lose or change its effects. Data-loggers are used to monitor the temperature. These are advanced USB-Sticks, which most of the time have a sensor to measure the temperature within the package. The data-logger is often inside of the package. This means the temperature can’t be tracked in real-time. After the delivery, the USB-Stick must be plugged in a computer to send a data-protocol.

Active cooling systems in pharma as part of a solution

Active cooling solutions have several advantages. With the push of a button, it’s possible to cool the goods to the designated temperature within minutes. This also secures from freezing the medication. Active cooling boxes do not need to be packed by trained personal; there is no inefficient energy need for packing thermal packs.

Electronic locks can prevent unauthorized access to the box and track the relevant parameters in real-time. These can be sent to a server, so it’s always at the users’ disposal. That way it’s possible to leave an active cooling box with RFID-lock and GPS-tracking in front of someone’s house door because it will easily keep cooling and is only accessible with a unique identification. In the case of a theft, the geo-location is tracked by GPS.

Beyond that, the active cooling box can be used for years before it must be replaced. This makes it a sustainable and ecofriendly solution, especially compared to the passive coolers.

Securing the e-commerce sector

Concerning the e-commerce sector, grocery retailers could rent active cooling boxes to their customers. As soon as there is a new delivery, the customer exchanges the box from the late delivery with the box from the original delivery. Another alternative possibility: the customer keeps one active cooling box over a more extended period. Whenever he gets a delivery, he puts the box outside, and it gets refilled by the retailer. Via data logging the customer can monitor whether the cold chain is unbroken when the delivery will take place and who is accessing his box.

Until now, the infrastructure of active cooling systems doesn’t cover a large area, and these ideas are meant for the future. Active cooling solutions can have a significant impact in reducing inner-city traffic, reducing environmental pollution through a sustainable delivery system and lead the way to a digital future of logistics.

With the NelumBox Tec4med is part of this innovative process. Find out more about how we build the future of last-mile active cold chain shipping here or contact us: info(at)tec4med.com.